Elevating Global Standards: The Rise of China's Best Hot Isostatic Pressing Technology

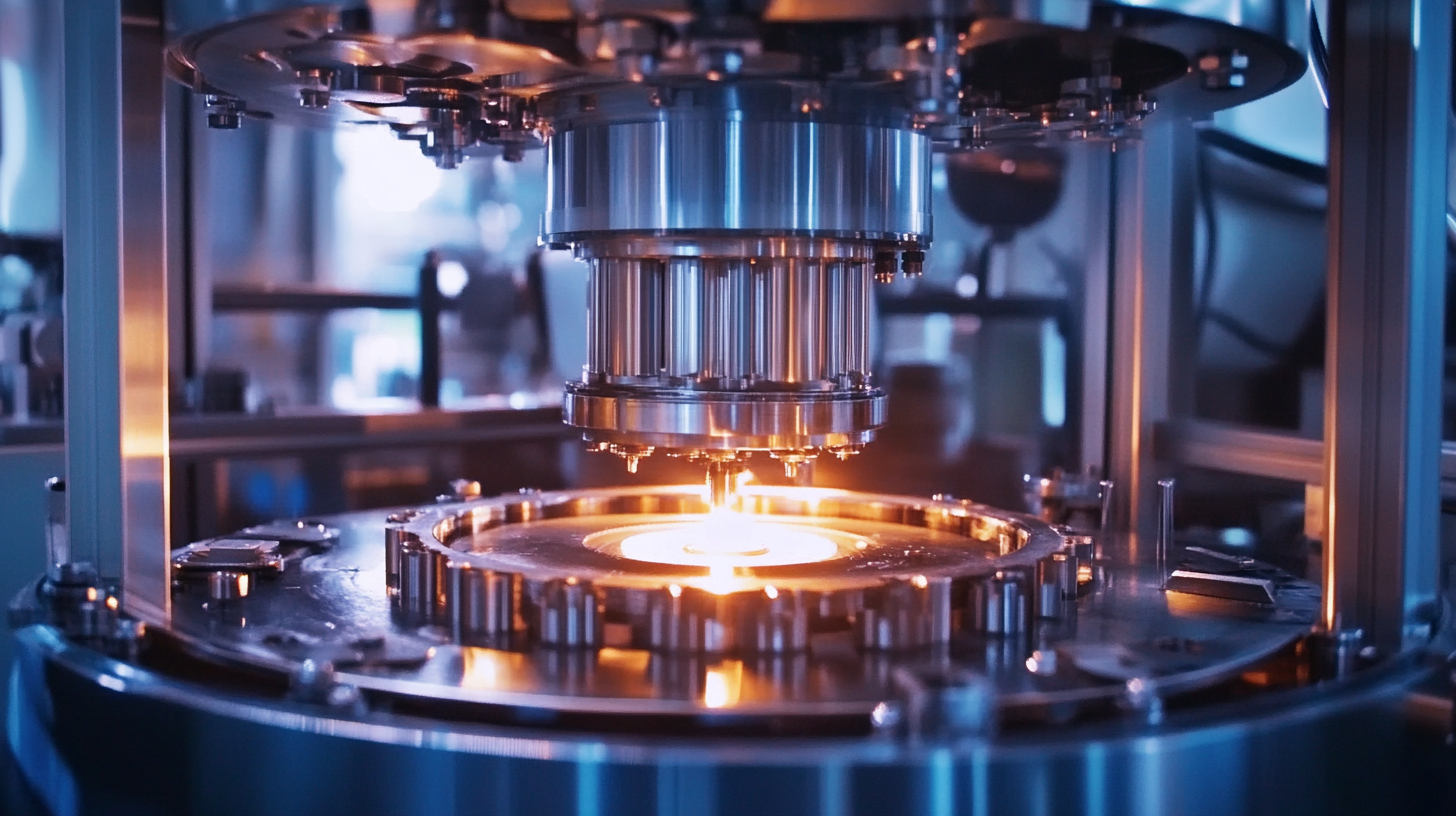

In recent years, China's advancements in manufacturing technology have positioned it as a leader in various industries, notably in the field of Hot Isostatic Pressing Process (HIP). This innovative method, which enhances the mechanical properties of materials by subjecting them to high temperatures and pressures, has garnered significant attention in sectors such as aerospace, automotive, and medical device manufacturing.

According to a report by MarketsandMarkets, the global HIP market is expected to reach USD 1.4 billion by 2025, growing at a CAGR of 5.9% from 2020. As the demand for high-performance components increases, Chinese manufacturers are not only meeting local needs but also setting global standards through their commitment to quality and technological excellence.

This blog will explore how China's best HIP technology is gaining trust worldwide, ensuring consistent quality and reliability in production.

Challenges in Adopting Hot Isostatic Pressing Technology Globally

The adoption of Hot Isostatic Pressing (HIP) technology worldwide faces several notable challenges. While the global HIP market is projected to reach $1.43 billion by 2027, growing at a CAGR of approximately 6.8%, disparities in technology access and operational expertise remain significant barriers (source: Market Research Future). Many industries still rely on traditional manufacturing methods due to the high initial investment costs and the complexity of integrating HIP processes into existing workflows. This creates a gap between advanced producers in regions like China and those in developing economies where such technologies are either inaccessible or underutilized.

Moreover, the skill set required to operate HIP machinery is not uniformly available across the globe. According to a report from Grand View Research, the need for trained personnel who can handle advanced manufacturing technologies is critical, yet supply lags behind demand. This lack of qualified workers can impede the efficiency and safety of HIP operations, further limiting widespread adoption. As nations aim to enhance production capabilities and materials performance, addressing these challenges will be crucial for fully leveraging the benefits of hot isostatic pressing technology.

Adoption Rates of Hot Isostatic Pressing Technology Globally

This bar chart illustrates the adoption rates of Hot Isostatic Pressing (HIP) technology across different regions. It highlights a significant lead in adoption within Asia, compared to other continents, depicting the varying levels of technology acceptance globally.

Comparison of China's Hot Isostatic Pressing to Global Standards

China's advancements in hot isostatic pressing (HIP) technology have positioned the country as a formidable player in the global market. As the isostatic pressing market continues to expand, with an estimated size of USD 7,495 million in 2023 and a projected compound annual growth rate (CAGR) of 7.3% from 2024 to 2030, it is crucial to examine how China's innovations compare to global standards.

Chinese manufacturers are not only increasing production capabilities but also enhancing the quality of HIP systems, which play a vital role in various industries, including aerospace, automotive, and medical. By optimizing processes and materials used in hot isostatic pressing, China is elevating the efficiency and reliability of this technology, aligning its offerings with international benchmarks.

A robust focus on research and development has allowed China to introduce systems that meet, and in some cases exceed, traditional performance metrics, paving the way for broader adoption domestically and abroad.

As global demand for high-performance materials rises, the significance of robust HIP technology becomes ever more pronounced. The competitive landscape underscores the need for constant innovation and adherence to international quality standards, which China is progressively achieving, thereby reflecting the country's commitment to elevating global manufacturing standards.

Overcoming Technical Barriers in Hot Isostatic Pressing Implementation

In recent developments, China's technological advancements in hot isostatic pressing (HIP) have overcome significant barriers, particularly with the launch of the HIPEX1850, the largest HIP equipment in the country and the second largest globally. This breakthrough positions China at the forefront of the advanced materials manufacturing sector, allowing for enhanced processing of large aerospace components. The advantages of HIP technology, which utilizes elevated temperature and pressure to improve material properties, are crucial for industries requiring high-performance materials.

Tip: When considering HIP technology for industrial applications, it's essential to evaluate the material compatibility and the specific performance requirements to maximize the benefits.

The introduction of such equipment signals a major shift in China's ability to compete globally in material processing technologies. Reports indicate that by leveraging these advanced capabilities, the nation is not only decreasing its dependency on foreign technologies but also positioning itself as a key player in high-tech manufacturing. This trend is expected to continually enhance China's competitiveness in the international market.

Tip: To stay competitive, industries should focus on integrating advanced manufacturing technologies, like HIP, which can lead to significant cost savings and performance enhancements in the production of critical components.

Impact of Quality Control on Hot Isostatic Pressing Processes

In the realm of advanced manufacturing, the role of quality control in Hot Isostatic Pressing (HIP) processes cannot be overstated. As China emerges as a leader in HIP technology, maintaining stringent quality control standards is essential for producing high-performance materials, particularly in aerospace and medical applications. Reports indicate that nearly 70% of defects in final products can be traced back to inadequacies in the HIP process, emphasizing the need for robust quality monitoring systems.

To enhance the quality of HIP processes, consider adopting real-time monitoring techniques. Implementing automated systems can significantly reduce human error and ensure that parameters such as temperature, pressure, and time are meticulously controlled. According to industry studies, companies that employ real-time data analytics report a decrease in defect rates by up to 25%.

Another critical aspect is regular equipment calibration. Ensuring that all machinery operates within specified limits is vital to achieving consistent quality outcomes. Research suggests that firms that adopt proactive maintenance strategies see an increase in operational efficiency by 15%, leading to reduced downtime and higher throughput. By prioritizing quality control, businesses can leverage China's cutting-edge HIP technology to retain a competitive edge in global markets.

Future Trends in Hot Isostatic Pressing and Their Global Implications

The field of hot isostatic pressing (HIP) is experiencing a significant transformation as China's technology continues to gain traction on a global scale. With advancements in materials science and engineering, the future of HIP is set to witness innovations that enhance efficiency and expand its applications across various industries. One notable trend is the integration of artificial intelligence and machine learning into the HIP process, enabling precise control over variables such as temperature and pressure. This shift not only improves the quality of the end products but also reduces energy consumption and operational costs.

Moreover, as China establishes itself as a leader in HIP technology, the implications for global manufacturing standards are profound. Increased competitiveness among manufacturers worldwide may lead to the adoption of superior practices and equipment, promoting a ripple effect that enhances quality and sustainability across the industry. As more companies recognize the benefits of HIP, we can anticipate a broader acceptance of these technologies, potentially leveling the playing field in global markets. The rise of China's best hot isostatic pressing technology may well redefine industry benchmarks, driving innovation and collaboration internationally.