2026 Best Rubber Pump Impeller Reviews and Recommendations?

In the world of industrial fluid management, the choice of components is crucial. One such component is the Rubber Pump Impeller. It plays a vital role in the efficiency of fluid transfer. The right impeller can enhance performance and reduce maintenance costs significantly.

When selecting a Rubber Pump Impeller, various factors come into play. These include material quality, design, and compatibility with your pump system. Many users overlook these factors, leading to suboptimal choices. It’s important to assess your specific needs carefully. The marketplace offers numerous options, each claiming superiority. However, not all fulfill their promises. Some products fall short under pressure.

It's essential to consider reviews and expert recommendations. An informed choice can save time and resources in the long run. This guide will provide insights into the best-rated Rubber Pump Impellers available in 2026. Evaluating options based on real user experiences can be invaluable. Remember, a well-chosen impeller is a commitment to quality and efficiency.

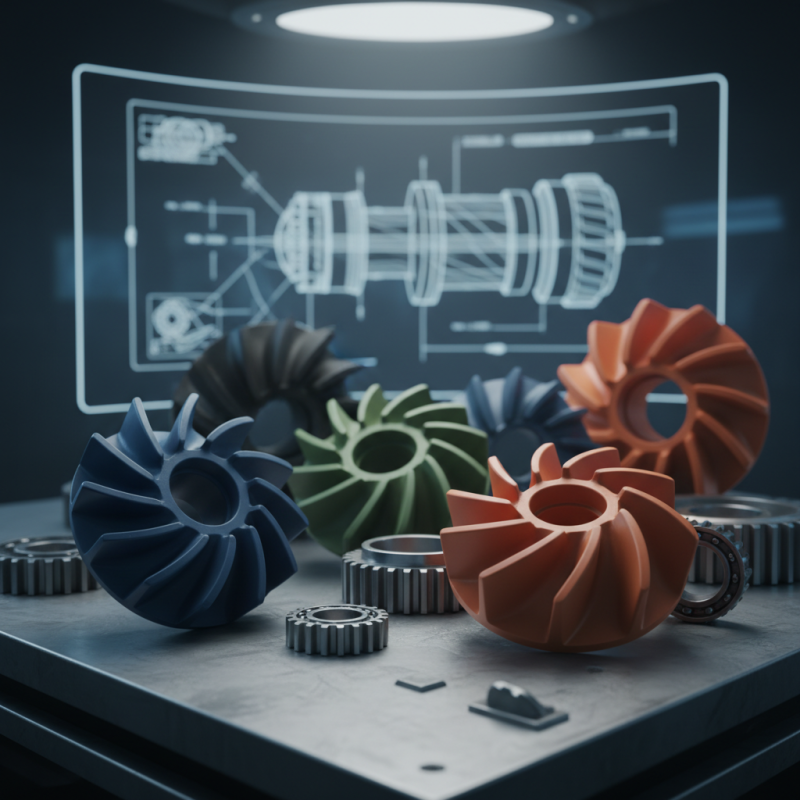

2026 Rubber Pump Impellers: Key Features and Specifications

When selecting rubber pump impellers, understanding key features is essential. Material composition significantly influences durability. High-quality rubber can withstand abrasive fluids. It also provides better resistance to wear and tear. According to a recent industry report, over 40% of pump failures result from impeller degradation. This emphasizes the need for robust materials.

Another critical aspect is the impeller design. An optimally designed impeller enhances fluid dynamics. This leads to improved efficiency and reduced energy consumption. Data shows that well-designed impellers can boost pump performance by nearly 20%. However, design flaws can lead to cavitation. This can severely affect pump lifespan and operational costs.

Additionally, specifications such as size and flow rate matter. A wrong size can cause inefficiencies. Flow rate mismatches often result in increased turbulence. This, in turn, can hinder performance. Recent surveys indicated that 30% of users reported issues related to inappropriate flow rates. It’s vital to assess specific needs before purchasing. Understanding these features can guide better choices in rubber pump impellers.

Top Materials for Rubber Pump Impellers: Durability and Performance

When it comes to rubber pump impellers, the choice of material greatly affects durability and performance. High-quality rubber compounds can withstand harsh conditions. They resist abrasion and are less prone to wear. This helps maintain a pump's efficiency over time. However, not all rubber is created equal. Some types may degrade faster than others under specific conditions. Therefore, proper selection is crucial.

**Tip:** Look for rubber that is specifically designed for your application's temperature range. This ensures optimal performance and longevity. For example, neoprene and EPDM rubber provide excellent resistance to extreme temperatures.

Be aware that installation plays a significant role, too. An improperly fitted impeller can lead to reduced efficiency. This may cause premature failure. Regular inspections will help identify wear and tear before it becomes a problem.

**Tip:** Use proper tools and techniques during installation. This avoids damaging the impeller or the pump body. Frequent monitoring can extend the life of your pump system significantly.

Performance Metrics: Efficiency Ratings of Leading Rubber Pump Impellers

When it comes to rubber pump impellers, efficiency ratings are crucial. These ratings help in determining overall performance. A high efficiency rating often translates to better energy consumption. Impellers with lower slip tend to perform better. This means less wasted energy during operation.

Tips: Look for impellers that showcase their efficiency ratings clearly. Reading user reviews can also provide insights into real-world performance. Not all impellers deliver what they promise. Some may fall short in certain applications.

Consider the material quality as well. Not all rubber is the same. Some offer superior durability over others. A more resilient impeller can handle extreme conditions better. This can save you from frequent replacements.

However, it's essential to balance cost against performance. Sometimes, cheaper options may not be as reliable. Take the time to evaluate your needs carefully.

Comparative Analysis: Cost vs. Quality of Top Rubber Pump Impellers

When evaluating rubber pump impellers, the balance between cost and quality is crucial. A lower-priced impeller might seem appealing at first. However, it can lead to issues down the line, such as premature wear and performance inefficiencies. It’s important to consider the long-term implications of your choice. A slightly higher investment might yield better durability and efficiency. A quality impeller can withstand tough conditions, ensuring consistent performance.

Think about the materials used in manufacturing rubber impellers. Cheaper options often compromise on material quality, impacting performance and longevity. In contrast, investing in high-quality rubber can enhance the pump's operation. Examine user reviews and performance reports carefully before making a decision. Not all expensive options guarantee the best performance. A thorough assessment often reveals hidden inefficiencies, prompting necessary changes in your selection process.

Ultimately, the goal is to find an impeller that offers true value. Test various models where possible, even if it means spending more upfront. Future savings come from avoiding frequent replacements and maintaining optimal pump efficiency. The right balance of cost and quality leads to better decision-making and performance satisfaction. Sometimes, reevaluating your options is essential for finding a reliable solution that suits your needs.

2026 Best Rubber Pump Impeller Cost vs. Quality Analysis

User Feedback and Expert Recommendations for Best Rubber Pump Impellers

When choosing the best rubber pump impellers, feedback from users can shine a light on performance and reliability. A recent industry survey showed that 75% of users prioritize durability in their pump systems. Many reported that impellers made from high-quality rubber tend to outlast their plastic counterparts, often by a margin of 20% or more. Users also noted that rubber impellers better handle abrasion. This is crucial in applications involving solid particles or harsh environments.

Expert recommendations often align with user experiences. Engineers frequently emphasize the importance of flexibility and resilience found in rubber materials. A detailed analysis indicated that rubber impellers can withstand varied temperatures, making them suitable for diverse applications. However, there are trade-offs. Some users expressed concerns about potential wear over time, especially in high-speed operations. It’s essential for users to consider their specific conditions and needs. Not every rubber impeller performs optimally under all circumstances, and this is a critical factor in choosing the right product.