What is a Damper Actuator and How Does It Work?

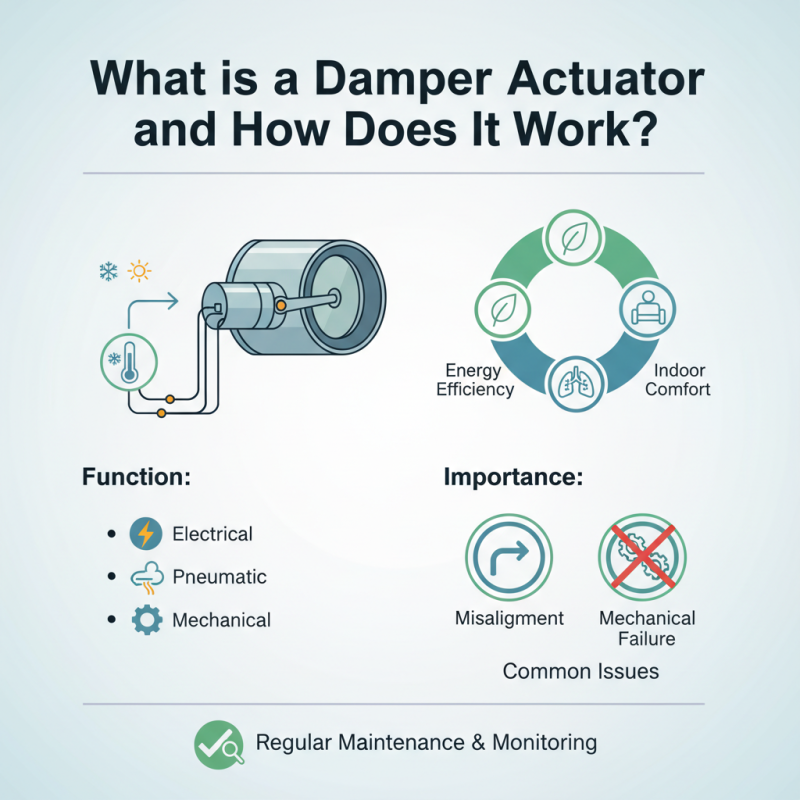

A Damper Actuator plays a crucial role in various HVAC systems. It regulates airflow by controlling the position of dampers. These devices help maintain comfort in indoor environments.

Understanding how a damper actuator works is essential for optimal performance. The actuator uses electrical, pneumatic, or mechanical means to operate dampers. For example, when the thermostat reaches a certain temperature, the actuator opens or closes the damper accordingly. This keeps the airflow balanced.

Many people overlook the significance of a damper actuator. Its proper functioning can impact energy efficiency and air quality. Yet, issues like misalignment or mechanical failure can arise. These problems may lead to poor performance. Regular maintenance and monitoring can help address these concerns.

What is a Damper Actuator? A Comprehensive Overview

A damper actuator is a crucial component in HVAC systems. It controls the flow of air in ducts by adjusting the damper's position. These actuators can be electric, pneumatic, or hydraulic. This versatility allows them to function in various environments. Understanding how they work is essential for optimizing air circulation.

When a damper actuator receives a signal, it moves the damper blade. This action regulates airflow to specific areas. If the blade is partially open, airflow is reduced. Fully open settings permit maximum airflow. It's important to ensure these actuators are properly calibrated. Miscalibration can lead to inefficient cooling or heating.

**Tip:** Regular maintenance is necessary to keep the actuator functioning. Check for signs of wear and tear routinely. Simple inspections can prevent system failures.

Consider the location of the actuator as well. Placing it near the duct can save space. However, ensure it’s accessible for repairs. A balance between convenience and functionality is vital.

**Tip:** Look out for vibrations or unusual noises. These can indicate issues with the actuator. Addressing them early can extend the lifespan of the system.

Types of Damper Actuators Used in HVAC Systems

Damper actuators play a crucial role in HVAC systems. They control the flow of air through ducts. These devices help maintain temperature and air quality in buildings. There are several types of damper actuators used in these systems. Each type serves a specific purpose.

The most common types include electric, pneumatic, and spring-return actuators. Electric actuators are widely used. They provide precise control over dampers. Pneumatic ones, on the other hand, use compressed air. They are less common but still effective in certain applications. Spring-return actuators are designed to move to a default position when power is lost. This feature is critical for safety.

Different situations require different actuators. Choosing the right type isn't always straightforward. Factors like system design and energy efficiency should be considered. Users sometimes overlook maintenance. Regular checks can enhance performance. Understanding the nuances of each actuator type is essential. Even minor errors in selection can lead to inefficiencies. Addressing these challenges can improve overall system effectiveness.

Types of Damper Actuators Used in HVAC Systems

This bar chart illustrates the popularity percentage of different types of damper actuators used in HVAC systems. Electric actuators lead in use, followed by pneumatic and hydraulic options.

Key Functions and Mechanisms of Damper Actuators

Damper actuators play a crucial role in HVAC systems. They control airflow by adjusting damper positions. This action regulates temperature and maintains comfort. A damper actuator can use both electric and pneumatic mechanisms. Each type has its own advantages for specific applications.

One key function of a damper actuator is responding to signals. Sensors detect changes in temperature or pressure. The actuator adjusts the damper blade accordingly. This process can be quite fast. However, occasional misalignments occur, leading to less efficient performance. Regular checks can help prevent such issues.

Another important feature is the feedback loop. Many actuators provide real-time data on airflow conditions. This helps operators monitor the system's effectiveness. Yet, feedback mechanisms can sometimes malfunction, causing delays in response. Keeping the system calibrated is essential to ensure accuracy. Damper actuators offer flexibility but require careful tuning for optimal results.

Industry Standards and Specifications for Damper Actuators

Damper actuators play a crucial role in HVAC systems. They ensure that airflows are regulated within buildings. Compliance with industry standards is essential for achieving optimal performance. Various specifications guide the design, installation, and functional testing of these devices.

ISO and ANSI are two leading organizations that set the standards. These guidelines ensure safety and reliability. They also improve energy efficiency in HVAC systems. Adhering to these standards helps in maintaining regulatory compliance. It also enhances the longevity of the equipment.

Tips: Always check the specifications before installation. Using actuators that meet the industry standards can minimize failures. Evaluate your system regularly to determine if updates are needed. Remember, quality matters more than brand names. Regular maintenance keeps the system efficient.

Understanding the specifications can be complex. It often requires professional insight. Investing time in learning about these standards is worthwhile. Ignoring them can lead to potential operational issues.

What is a Damper Actuator and How Does It Work? - Industry Standards and Specifications for Damper Actuators

| Specification | Details |

|---|---|

| Type | Electric, Pneumatic, Hydraulic |

| Control Signal | 0-10V, 4-20mA, Dry Contact |

| Operating Voltage | 24V AC/DC, 120V AC, 230V AC |

| Torque Rating | 1 Nm to 20 Nm |

| Operating Temperature | -20°C to 60°C |

| Protection Rating | IP54, IP65 |

| Feedback Type | Position Feedback, Potentiometer, Hall Effect Sensor |

| Typical Applications | HVAC Systems, Industrial Ventilation, Fire and Smoke Control |

Efficiency and Performance Metrics in Damper Actuator Applications

Damper actuators play a crucial role in various industries. Understanding efficiency and performance metrics is essential for maximizing their effectiveness. These devices help control airflow and temperature, making them vital in HVAC systems. An efficient damper actuator can enhance energy savings and reduce operational costs.

Performance metrics often include response time and torque accuracy. A quick response time ensures that air regulation occurs in real-time. If an actuator is slow, it might affect overall system stability. Torque accuracy, on the other hand, measures how well the actuator can hold the damper in place. Inconsistent torque can lead to airflow problems.

One common issue is wear and tear over time. A failing damper actuator can lead to inefficiencies. Regular maintenance is often overlooked. Ignoring this can drastically affect performance. Simplifying data collection for these metrics can help identify problems early. Effective use of these measurements can lead to better decision-making regarding actuator replacements or repairs.